Portable Russian Welding Transformer TSB-90-1U3

The russian welding transformer type “TSB-90-1U3” is an industrial manufacturing welding equipment. It is designed for manual metal arc welding (MMA), in alternating current, of low carbon steels with thickness less than 3mm, using 2-3mm electrodes.

Quick welding specs

- MMA welder

- low carbon steels with maximum thickness of 3mm

- 2-3mm electrodes

Technical specifications

- Nominal supply voltage – 220 V.

- Frequency – 50 Hz.

- Numar of phases – 1

- Idle voltage – 42V

- Maximum idle current – 1 A.

- Rated current in primary – 16 A

- Rated welding current – 90 A

- Welding current steps:

- I – 60 A (2mm diameter electrodes)

- II – 75 A (2mm-2.5mm diameter electrodes)

- III – 90 A (2.5mm diameter electrodes)

- IV – 100 A (3mm diameter electrodes)

- Active work cycle length:

- I – 30%

- II – 25%

- III – 20%

- IV – 15%

- Work cycle time – 5 minutes

- Power factor (Step III) >0.45

- Power factor (Step IV) >0.85

- Efficiency/Yield (Step III) >55%

- Transformer power consumption at rated load, nominal voltage – 3.5 kVA

- Dimensions:

- 340mm (length)

- 390mm (width)

- 190mm (height)

- Weight – 30 kg.

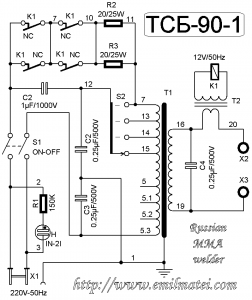

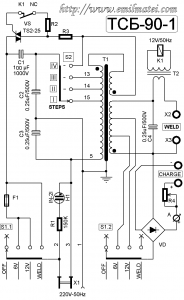

Schematic diagram of TSB-90-1U3 Russian welding equipment

(version 1)

Welding transformer TSB90-1 is distinguished by an original scheme of reactive power compensation.

Capacitor C1 is connected in series with the primary winding of the transformer. In the welding process, thies creates a system close to resonance voltage, raising to double the voltage on this winding.

At idle, the capacitor C1 is shorted by resistors R2, R3, lowering down the output voltage to a safe value (under 42V). This is a not dangerous voltage from the point of view of labor protection .

At presence of welding current, the K1 relay, mounted on the current transformer secondary T2, is actuated. Its 4 relay contacts open, so the resistors R2, R3 are disconnected from the circuit, activating the oscillating circuit.

Capacitors C2 and C3 are used for suppresion/filtering. Their purpose is to decrease specific electromagnetic disturbances (RFI).

Photos

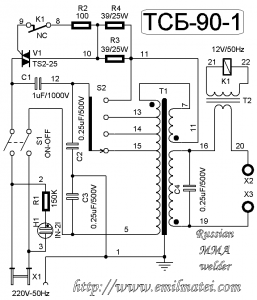

Schematic diagram of TSB-90-1U3 Russian welding equipment

(version 2)

An upgraded version, which considerably reduces the current through the contacts of the current relay, uses a gate-controlled triac through one of the relay contacts.

Schematic diagram of this triac version of the welding equipment:

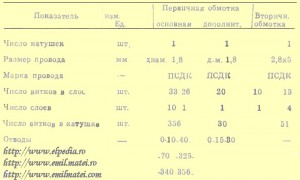

About transformer T1:

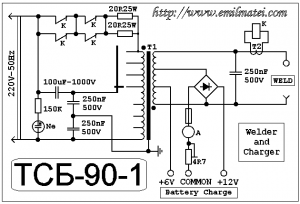

The transformers presented above, are also used for charging the battery voltage of 6V and 12V. (welding transformers incorporates a battery charging rectifiers). Control limits the charge current, in the range of 6V are 0,7-3 Amper. Control limits the charge current, in the range of 12V are 1,5-6 Amper.

Welding transformers HOUSEHOLD TSB-90-1 type TDZ-901U3

There are some Russian welding transformers which also incorporate a battery charging rectifier. Below are a few versions.

Overview

Transformer TSB-90-1 type TDZ-901U3 is designed for manual arc welding with alternating current in a conditions of low carbon steels with a thickness of 3 mm electrode diameter of 2 to 3 mm, and for charging the battery 6 Volt and 12 Volt with the charge current does not over 6 A.

Symbol structure:

TSB-90-1 – type TDZ-901U3:

TSB-90-1 = the project number,

the TDZ = Arc welding transformer with charger;

9 – rated welding current of tens of amperes,

01 – registration number;

U3 – climatic version and category according to Russian Standard GOST 15150-69.

Operating conditions:

In confined spaces with natural ventilation without artificially controlled conditions.

– Altitude of 1,000 m max.

– Ambient temperature -40 to 35 ° C – during welding and from -5 to 35 ° C during charging.

– Maximum relative humidity more than 70% at a pressure of not more than 133.332 kPa (1000 mm Hg. cent.).

– Tolerance of the room is more than one of the signs that create an increased danger: Damp or conductive dust, continuous high temperature over 35 ° C.

The possibility of simultaneous touch a person to have a connection to the land metalworkers buildings mechanisms on the one hand and the metal frame of the welding transformer on the other side. Safety requirements of GOST 12.2.007.8-75.

Transformer meets the requirements of TU 16-739.196-79.

Reference document TU 16-739.196-79

Technical characteristics:

Rated voltage of a single-phase supply voltage, 220V

Rated frequency, 50 Hz

Rated welding current, 90 A

Welding current at the rated voltage power line, on the steps of regulation:

1st – 60 A,

2nd – 75 A,

3 – th – 90 A,

4th – 100 A.

Rated duration of the load cycle, on the steps of regulation:

1st – 30 %,

2nd – 25 %,

3rd – 20 %,

4th – 15 %.

Cycle welding – 5 minutes

No load voltage at nominal voltage supply, max – 42V,

No-load current, max – 1 A,

Rated current, – 16 A

Range of charging current, in range 6V – 0,7-3 Amp,

Range of charging current, in range 12V – 1,5-6 Amp.

Charger voltage at nominal value of the rectified voltage,in the range of 6V – about 7.5 V,

Charger voltage at nominal value of the rectified voltage,in the range of 12V – about 15 V.

Power consumption of the transformer at rated load and nominal line voltage – 3.5 kVA

Power Factor, not less than the nominal level for the welding current “diameter 2.5” – 0.5

Power Factor,at the maximum level of welding current “diameter 3” – 0.75

Efficiency at nominal level of welding current “diameter 2.5” not less than- 55 %

Average service life – 5 years

MTBF, not less – 1500 hours

Weight – 30 kg

Design and Function

The ground transformer is a metal frame, which includes: a transformer,capacitor panel with elements of automation, control panel with mounted measuring instrument control charge current indicator and mode switch welding, located on the wall with her clamps to connect welding cables, cord power outputs for connecting wires to charge and fuse cover with decorative cover.

Transformer consists of a magnetic core, primary and secondary windings.

The primary winding is tapped to provide a step of welding current, the secondary winding – for receiving and removing the welding current during welding implementation.

Primary winding of the transformer in conjunction with a capacitor forms a series circuit with a natural frequency close to the frequency of the mains. Depending on the requi red welding current is switched capacitor with a switch to the appropriate tap of the primary winding.

At the start of welding (ignition) relay contacts are open, and when the arc is broken (stop welding) contacts close. Transformers provide a steady burning arc.

Schematic diagram of TSB-90-1 type TDZ-901U3

(TSB-90-1 version 3)

It is a development version (1) by adding Section battery charging.

Schematic diagram of TSB-90-1 type TDZ-901U3

(TSB-90-1 version 4)

It is a development version (2) by adding Section battery charging.

Buna ziua.

Sunt din Bucuresti si doresc sa stiu de unde pot achizitiona un condensator de 100uf la 1000v , pt. aparatul de sudura rusesc TSB-90-1 version 3, cu incarcator auto. Am citit pe elforum comentariile dvs. despre aceste aparate si as dorii sa reglez si sa curat contactele releului care sunteaza condensatorul C1, de 100uf.

Va multumesc

Dragos B.